Insulation material cutter

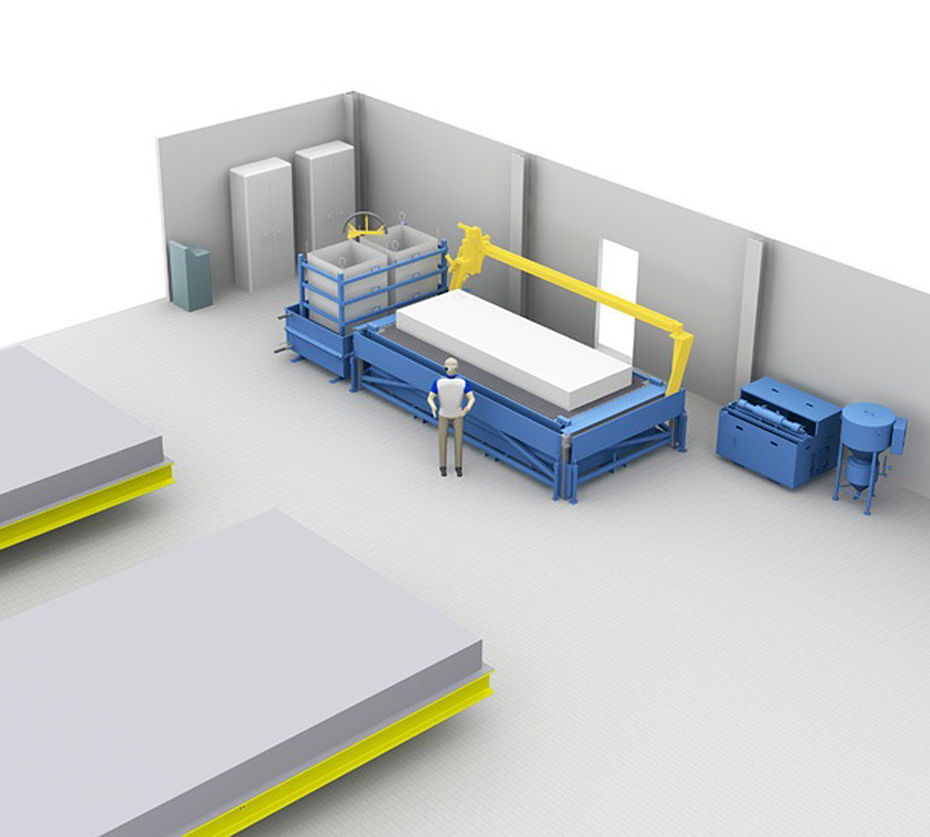

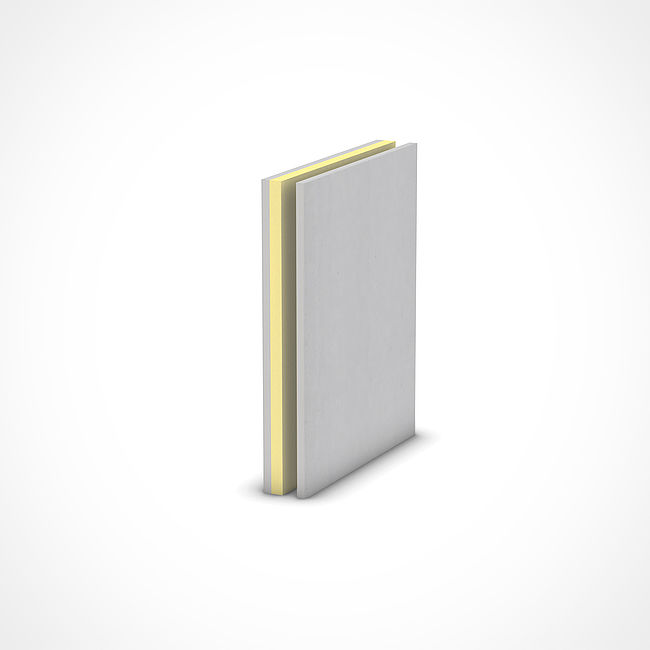

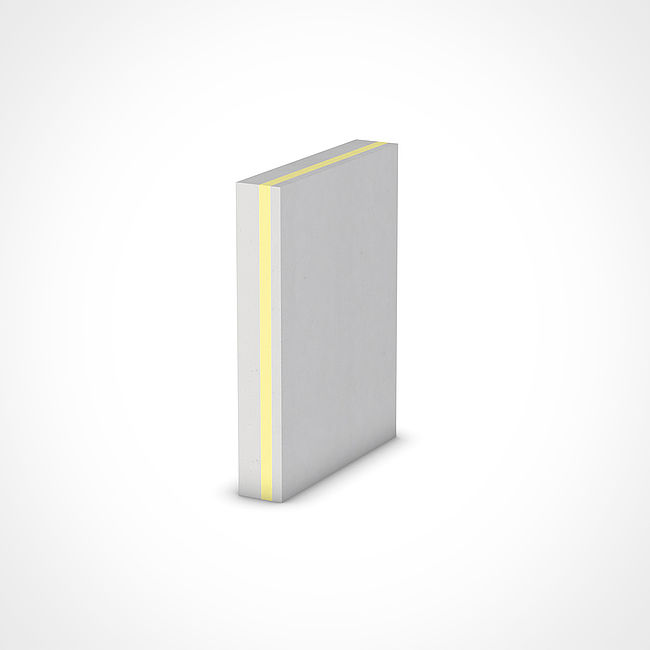

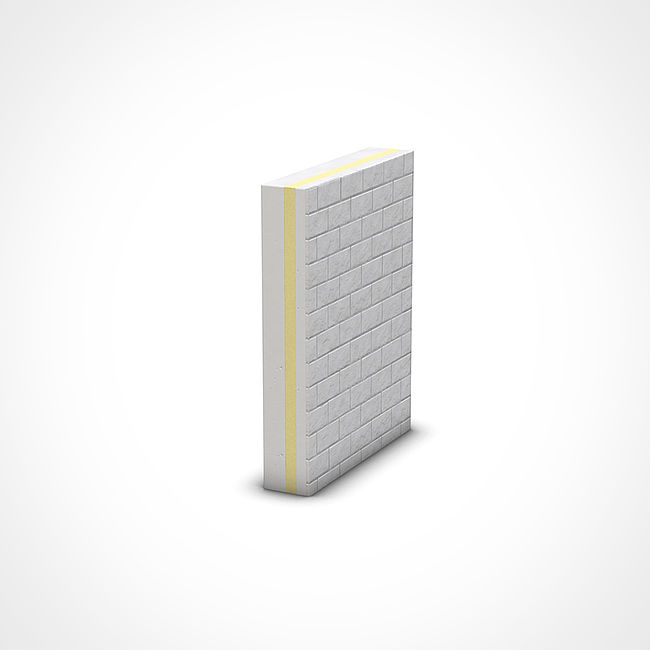

Sustainable construction is increasingly demanding concrete elements with integral insulation. For this insulated double walls and sandwich elements are used. Our insulation material cutter cuts the necessary insulation with precision just-in-time and saves material and staff. Different insulation materials are cut in a specially developed water jet cutting method.

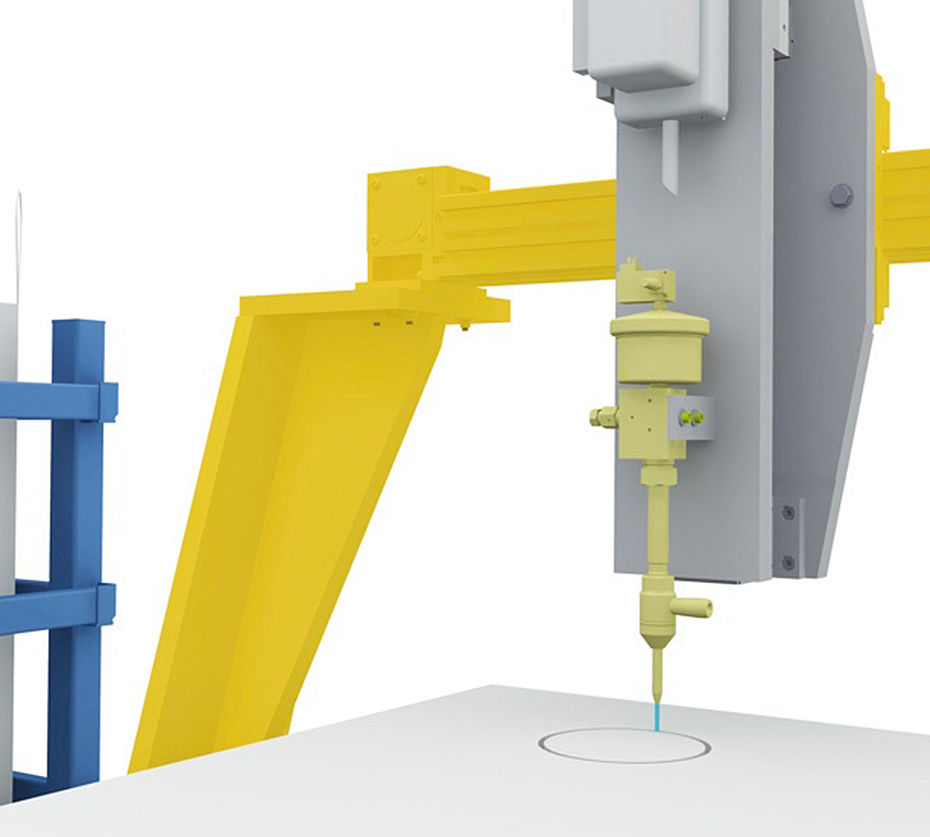

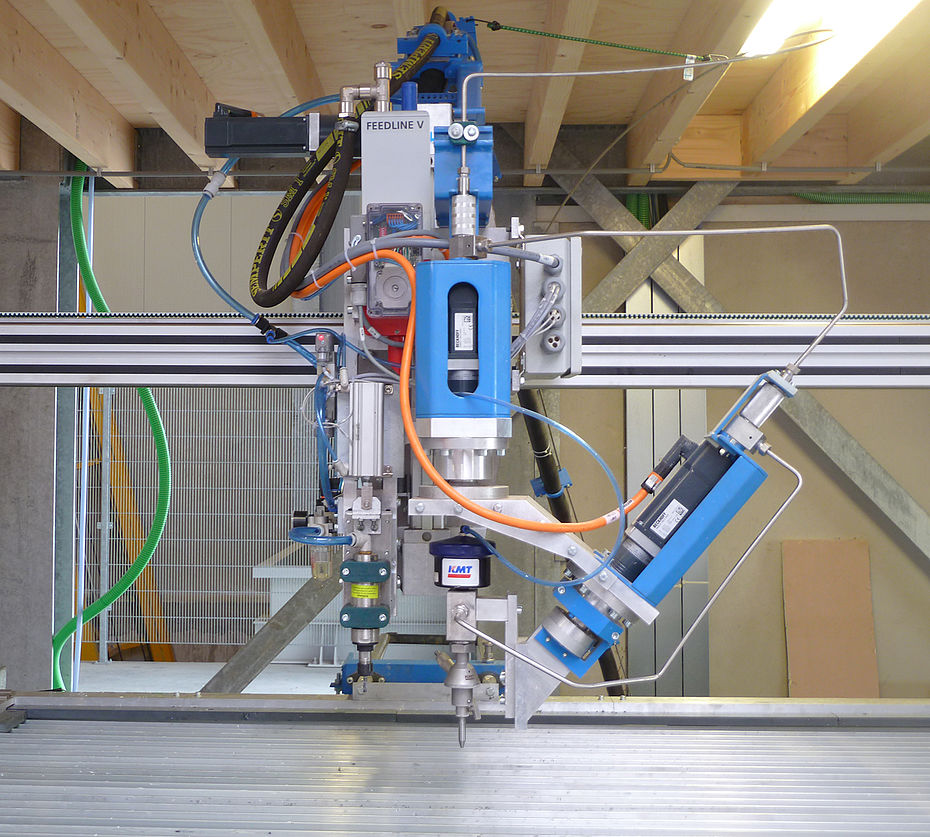

The insulation material cutter can process the widest variety possible of insulation materials, such as polystyrene, PU foam and mineral wool, using the water jet cutting method. The cutting head separates the insulation plates not only with straight or circular cuts or cuts on the bias, but also drills holes in the insulation material. The software supplied for this purpose reads the CAD data supplied by ebos®, identifies the insulation plate to be processed and autonomously generates all the data needed for the production process.

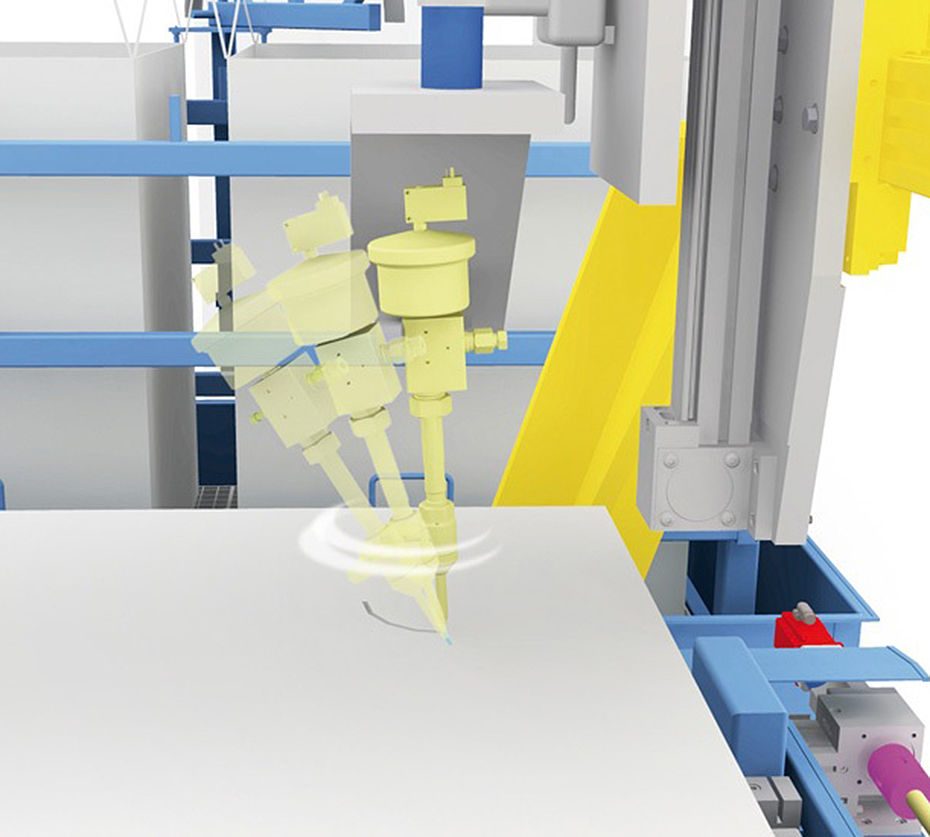

The 3D cutting head also allows three-dimensional cutting processes. For materials with greater solidity the insulation material cutter can be fitted with an abrasive system, which changes the cutting system from water to sand.

Thus, the insulation material cutter saves time, material clippings and high labour costs in the production process.

Precision cutting out by a CAD based system

Huge cost savings in material and staffing

Fewer waste